HI, We're

A Phase Difference of Arrival (PDOA)-based System for Enhancing Construction Safety

wHAT is salt?

SALT is a proposed safety solution for construction sites that aims to provide real-time situational awareness to reduce accidents involving heavy machinery and workers. It employs Ultra-Wideband technology, Bluetooth Low Energy communication, and Inertial Measurement Units.

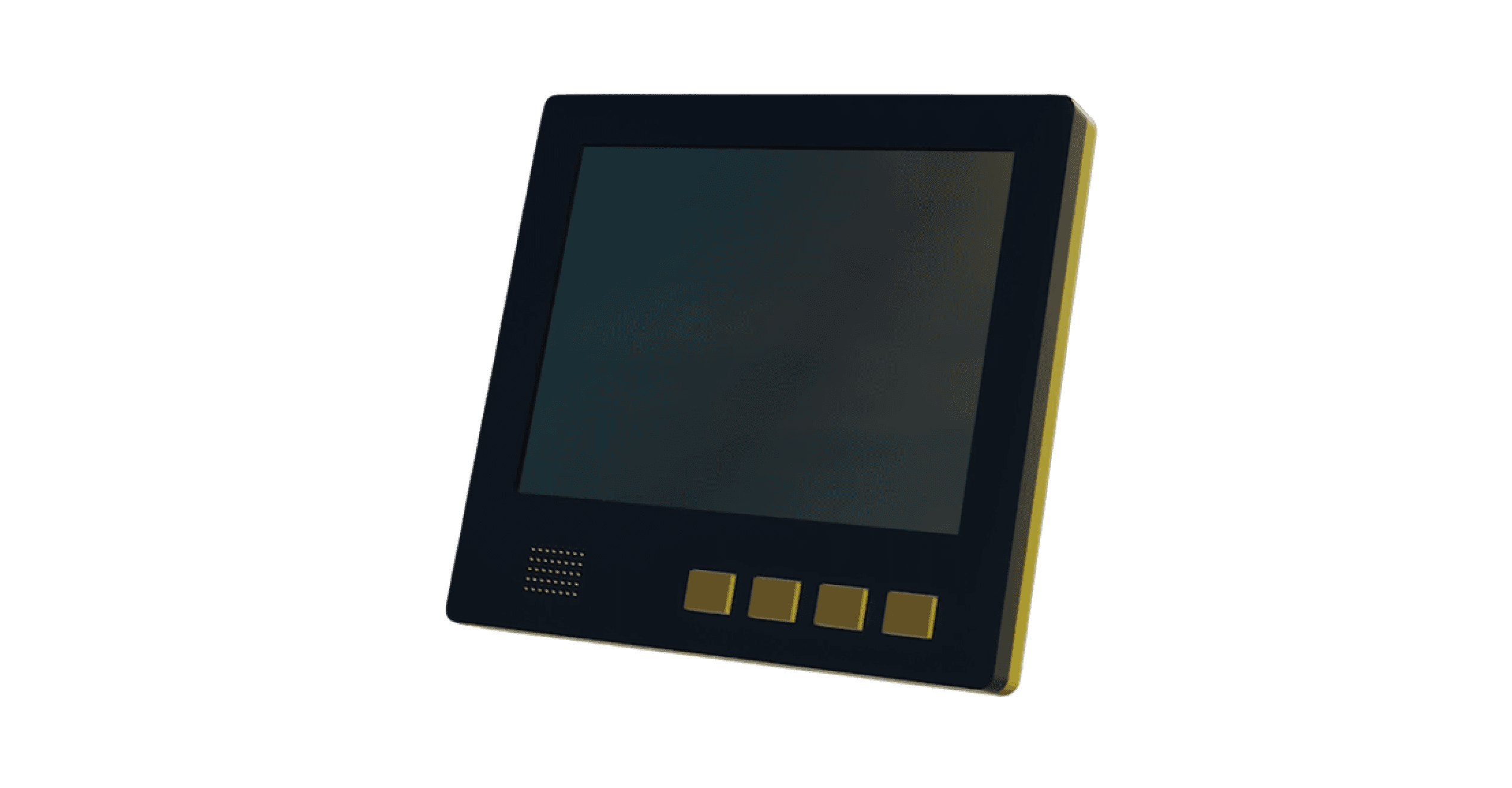

The SALT system comprises three primary hardware components: the tag, anchor, and display. The anchor provides 360-degree coverage by utilizing three boards and algorithms, each covering a 120-degree Field of View (FOV). Employing UWB Phase Difference of Arrival (PDoA) technology, the anchor determines the tag's location and transmits it, along with Inertial Measurement Unit (IMU) data, to the display for enhanced situational awareness.

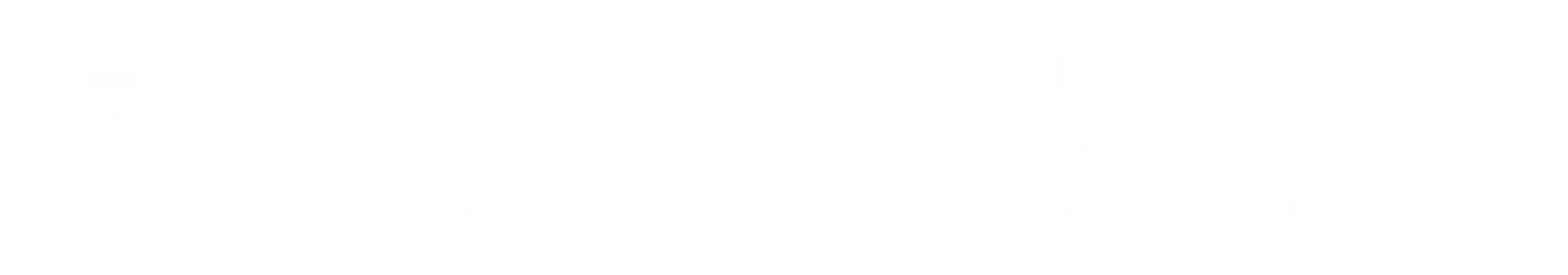

The SALT tag uses Bluetooth for long-distance communication while searching for the anchor, and switches to UWB upon detecting the anchor. The wirelessly charged tag also features buttons for status changes and a beeper to alert workers. Both the anchor and the tag are waterproof and shock-resistant, ensuring adaptability to various site conditions. The SALT display features a Thin Film Transistor (TFT) monitor that incorporates a Raspberry Pi Zero board, a waterproof speaker, and four operational buttons. These buttons enable users to adjust the detection range and issue warnings to workers, enhancing overall safety. The display is designed to accommodate an unlimited number of tags, dynamically adjusting based on the number of workers in proximity to the anchor.

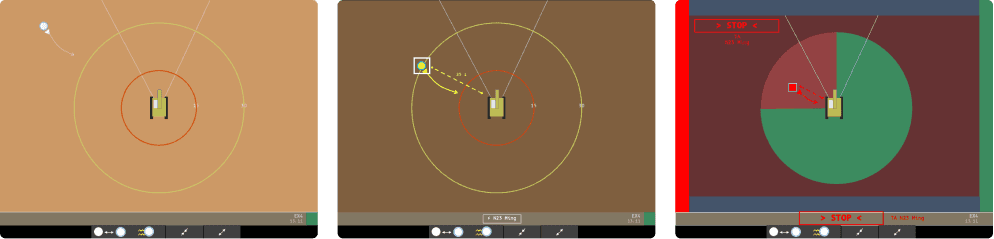

The SALT Display UI showcases three safety levels, from left to right: Safe Zone, Warning Zone, and Danger Zone. The UI not only displays the positions of workers but also predicts their movement directions using a long arrow, thanks to a specialized algorithm. When a worker enters the Warning Zone, their position is marked directly on the display, and the actual distance is shown.

In this stage, the screen starts to blink slowly as an alert. If a worker progresses into the Danger Zone, their location is prominently displayed on the cabin display, along with visual and audio alerts for both parties. Additionally, the screen undergoes a significant colour change to indicate the direction in which the driver should exercise heightened awareness.

The development of the SALT system was made possible through collaboration with various external parties. The team would like to acknowledge the invaluable contributions of advisors, faculty members, and domain experts who provided guidance, feedback, and insights throughout the project. Additionally, the team recognizes the importance of existing safety solutions that served as inspiration for the development of the SALT system.

Course advisor: Chi Ying TSUI, Chi Ming CHAN, Jac Leung, Ming CHAN

Course sponsor: SOCAM Development Limited

Student Helper: Chan Ming Chun

Interviewees: Cheng Tak Sum (Senior Construction Manager) from Zhuhai Engineering Limited,

(Former Safety Officer) from Fortune Jet Management & Training Co. Limited

Pang Yu Yin, LIU Pak Hin, MA Sze Long, SZE Chung Lam, CHEUNG Ho Hin